| Product Code | Description | Size | Pieces |

| TDB4000 | TD Board Only R1.0 (PU) | 4000mm x 1200mm x 20mm | 6 |

| TDiB4000 | TD Board Only R1.5 (PIR) | 4000mm x 1200mm x 20mm | 6 |

In the advanced world today, many different materials and systems have been developed as an alternative to the galvanized sheet metal traditionally used. One of the simplest, effective and economical alternatives is TD Pre- Insulated Aluminium Duct. It specializes in the air distribution fields as well as other insulation purposes. TD Pre-Insulated Duct is the solution to your needs.

TD Pre-Insulated duct is a double skin pre- insulated sandwich panel, made with two main materials (PU - Polyurethane & PIR - Polyisocyanurate) which are composed of three layers. The top and bottom layers are made up of embossed aluminium foil of 80 microns in thickness. There are two alternatives for the middle layer of foam insulation material. 1. TD Pre-Insulated Duct Board - PU - Polyurethane 20mm Thick (R1.0 & 4 zero) 2. TDi Pre-Insulated Duct Board - PIR - Polyisocyanurate 20mm Thick (R1.5 & 4 Zero) Both these solutions have been fully tested to comply with all relevant standards by both VIPAC & AWTA.

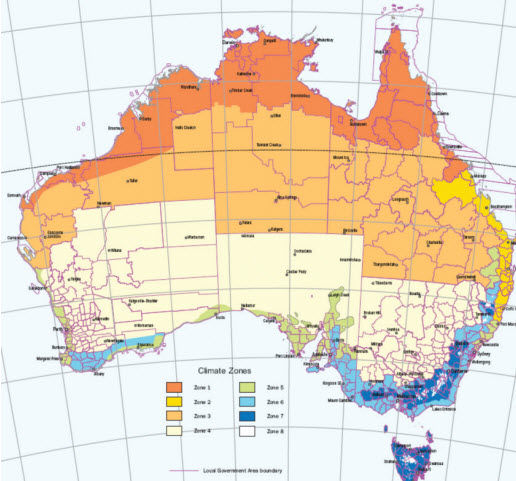

The table below indicates the BCA requirements for each climate zone.

| Table 3.12.5.2 Heating and Cooling Ductwork and Fittings - Minimum Total R-Value |

| Ductwork element | Minimum Total R-Value for ductwork and fittings in each climate zone |

| Evaporative cooling system | Heating-only system or refrigerated cooling- only system | Combined heating and refrigerated cooling system |

| All climate zones | 1,2,3,4,5,6 and 7 | 8 | 1,3,4,6 and 7 | 2 and 5 | 8 |

| Ductwork | 0.6 | 1.0 | 1.5 | 1.5 (see note) | 1.0 | 1.5 |

| Fittings | 0.4 |

Note: The minimum Total R-Value required for ductwork may be reduced by 0.5 for combined heating and refrigerated cooling systems in climate zones 1,3,4,6 and 7 if the ducts are:

(a) under a suspended floor with an enclosed perimeter; or

(b) in a roof space that has insulation of not less than R0.5 directly beneath the roofing. |

TD Pre-Insulated Aluminium Duct offers extremely good consistency of density throughout the sheet. The TD Pre- Insulated Aluminium Duct also has the foil applied in the initial manufacturing process ensuring an even and consistent application across the whole sheet & ensuring that the foil does not delaminate. The tables below outline the key properties for both types of board.

Key properties of the TD Pre-Insulated Aluminium Duct

| TDB4000 (R1.0) 20mm Thick Polyurethane |

| Sheet Size | 4000mm x 1200mm |

| Thickness Of Panel | 20mm |

| Density Of Polyurethane | 70.3Kg/m3 +/- 2 |

| Compressive Strength | 200N/mm2 |

| Thermal Conductivity | 0.021 W/m C |

| Flame Retardant | B1 |

| Friction Coefficient | 0.0135 |

| Working Temperature | -60 + 80 Deg C |

| Humidity Range | 0-100% |

| Max Pressure Drop In Duct | 2000pa |

| Max Airflow | 12m/s |

| TDiB4000 (R1.5) 20mm Thick Polyisocyanurate |

| Sheet Size | 4000mm x 1200mm |

| Thickness Of Panel | 20mm |

| Density Of Polyisocyanurate | 71.49Kg/m3 +/- 2 |

| Compressive Strength | 200N/mm2 |

| Thermal Conductivity | 0.0117 W/m C |

| Flame Retardant | Class 0 |

| Friction Coefficient | 0.0135 |

| Working Temperature | -60 + 80 Deg C |

| Humidity Range | 0-100% |

| Max Pressure Drop In Duct | 2000pa |

| Max Airflow | 12m/s |

The TD Pre-Insulated duct is available in three forms. Board only, supplied in sheets 4000mm x 1200mm x 20mm to allow you or your customer to fabricate in house. Quality Air Equipment is also offering the option of Flat Pack products & Fully Assembled products depending on your particular needs. QAE has invested in an efficient & highly accurate CNC Routing Machine that allows us to produce quickly, efficiently & cost effectively all product requirements including air conditioning & ventilation duct work. This together with a wide range in assembly extrusions, tools & ancillaries offers a full and comprehensive solution to all your needs.